Table of Contents

Rotary Motors

The most common form of electrical motors are rotary motors. Rotary motors can be designed to operate on DC power, AC power, or both.

Principles of Operation

The majority of electric motors operate using electromagnetic principles. Every motor contains at least two parts: a rotor, which is a cylindrical coil of wire which spins around its axis; and a stator or armature, which is a static housing which creates a magnetic field. The interaction of the magnetic fields generated by the rotor and the stator create the motive force which causes the rotor to spin1).

The rotor is divided into two sections, which are wired in opposite polarities. In order for the rotor to continue to spin, the polarity of the rotor's magnetic fields must reverse halfway through its rotation. In order to achieve this, a commutator is attached to the rotor. Electrical power is transferred to the rotor through conductive brushes which press against the commutator. The commutator is divided into several sections which are wired such that the current provided to the two halves of the rotor flips polarity when the brushes move onto a different part of the commutator.

The brushes in this design lead to several problems, including inconsistent transfer of power due to the nature of a brush pushing against a rotating object, loss of efficiency over time, and gaps in power output as the brushes move between commutator sections. Brushless motors were designed in order to remove these issues. In a brushless motor, the rotor itself is a permanent magnet and the stator consists of several coils of wire which reverse polarity every half-rotation of the motor.

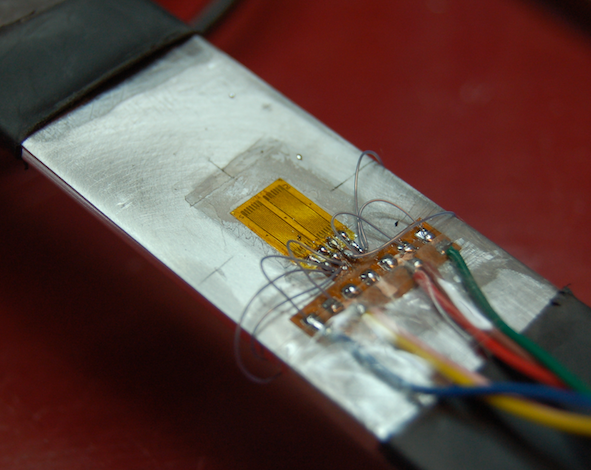

In order for the field of the stator to reverse polarity, it must know where in the rotation cycle the rotor is. Hall Effect sensors and rotary encoders are typical means of discerning this information. The data from the sensor is fed through a logic circuit and when the rotor is at the appropriate point a control signal is sent which reverses the magnetic fields present in the armature.

Rotary Motor Applications

Ottermo et al. used brushless electric motors were used to control the height of threaded rods in a tactile display.

As in this paper, brushless electric motors are often used to provide force feedback due to their high torque at stationary positions.